Rolling Mill alignment

Equipment, experience and best practices enable measuring of assembled rolling mills in the shortest possible period, during scheduled maintenance. This service offers the possibility to control accuracy of mill alignment in due time thus providing the best quality of finished products.There are increasing demands on contemporary steel grades, as well as on product quality, operating availability and production output for Rolling Mills. In order to remain competitive, new and existing plants should cope with the above-mentioned task the best they can.

Equipment, experience and best practices enable measuring of assembled rolling mills in the shortest possible period, during scheduled maintenance. This service offers the possibility to control accuracy of mill alignment in due time thus providing the best quality of finished products.There are increasing demands on contemporary steel grades, as well as on product quality, operating availability and production output for Rolling Mills. In order to remain competitive, new and existing plants should cope with the above-mentioned task the best they can.

The key part of steelmaking is hot strip production. Since most of steel (about 50%) is hot-rolled, the mills should be of maximum capacity and operational reliability combined with dimension accuracy and optimum material characteristics.

Moreover, most of mills operated in Russia are in function for decades. Main loads produced by rolling equipment have effect on stand frame.

Contemporary steel market places specific demands and manufacturers should satisfy them. There is a change in the guide of steel grades rolled at available equipment not designed for new steel grades. New steel grades bring modification of peak loads having effect on stand frame.

The present proposal is aimed at providing a complex of services in 3-D measuring of Rolling Mill by Laser tracker to be carried out by “New Measurements” LLC specialists. They include mill stand control, rolling line deviation to the extent enough to enable engineering to bring to original state.

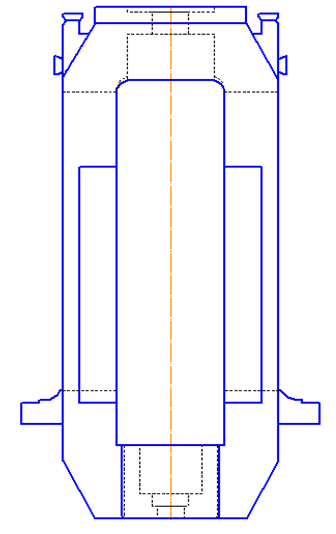

3-D measuring of dimensions and geometry for mill stand components to find areas to pay special attention to:

HGC cylinder axis

• Parallel alignment of housing columns

• Seats elevation

• Wear condition of housing surfaces

• Stands centering control

• Level alignment of back-up rolls changing rails.

• Dimensions of vertical and horizontal surfaces for housing window

Taking vertical axis as datum, we measure and get all necessary data on centering alignment of stand housings. The company specialists are well experienced in alignment of Pipe Hot Rolling Mills (continuous and sizing mills).

Adjustment of rolling axis and axial alignment of mills of one operating line. Alignment includes the following:

• Adjustment of bar steadier seats

• Adjustment of guiding plates for stands mounting

• Adjustment of centering screws

• Adjustment of stand housings according rolling axis

• Checking of assembled rolling mill

• Adjustment of stand housing seats

Application of laser tracker and NRK Spatial Analyzer software enabling 3D-modeling makes it possible not to use different types of templates and telescopic sights.

.